Innovation is change that unlocks new value.

Industrial AI | Process Technology Licensing

About Us

InnoVent Technology LLC is a USA based technology company established in 2020, providing Industrial AI solutions, Process Technology Licensing, and Engineering services, in chemical, oil & gas and renewable industries. Experienced executives with 25+ years of energy and chemical industry experience.

Operations in Houston-USA, Pune-India, and Monterrey-Mexico.

InnoSIM Industrial AI

Unified platform for process data historian, AI enabled digital twin asset monitoring, and process modeling.

Process Technology Licensing and Engineering

Process Technology Portfolio: Process engineering and technology licensing for bioethanol, Conceptual and feasibility studies, basic and detailed engineering and process safety studies.

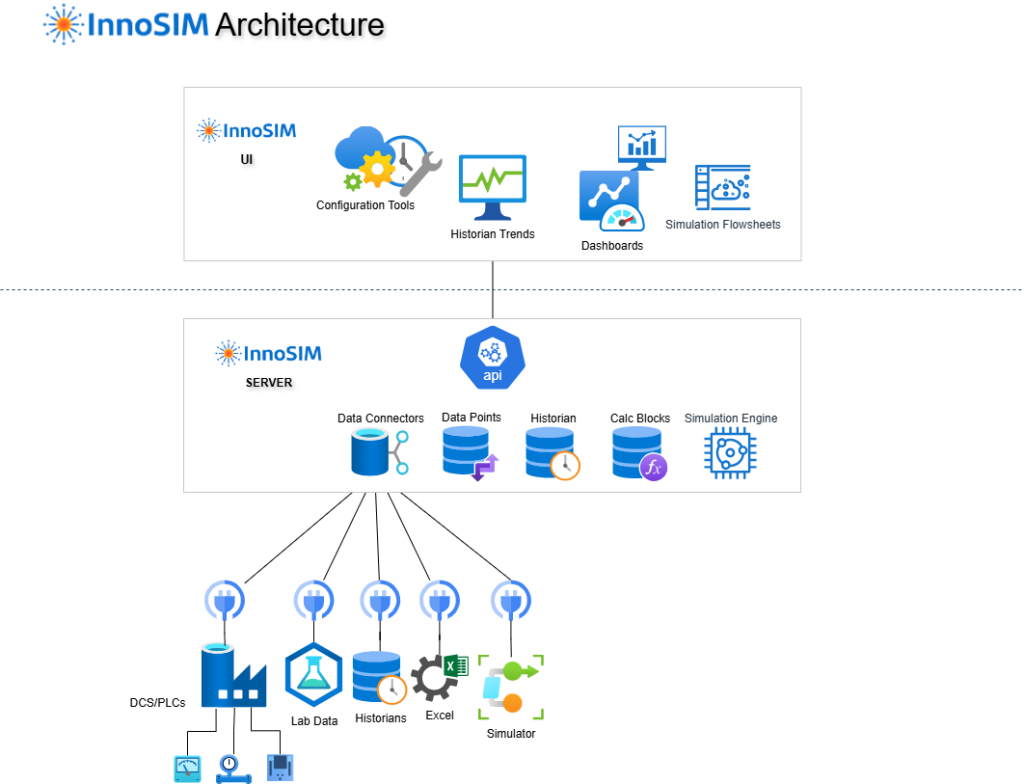

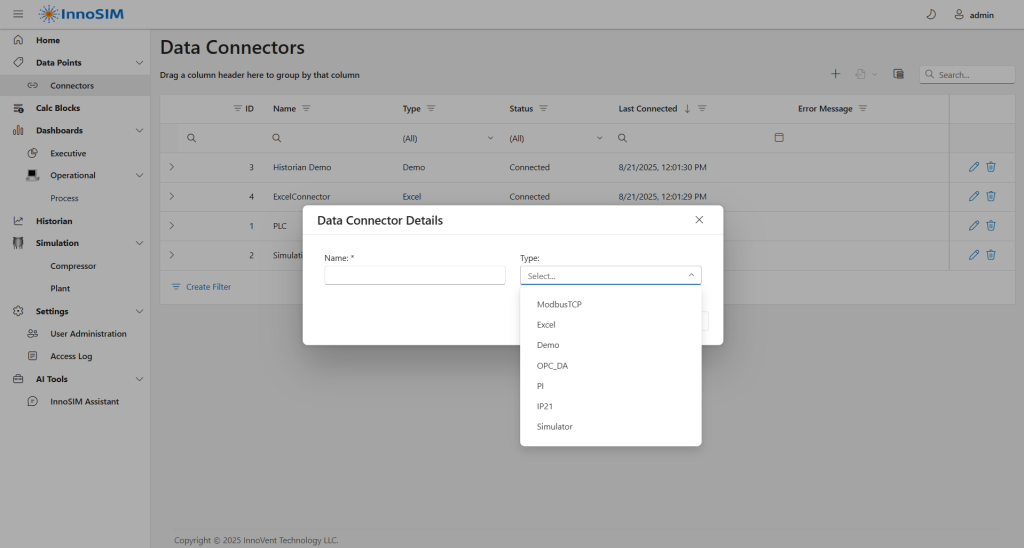

Industrial AI platform: InnoSIM

- Extracting data from multiple sources such as PLC and control systems, Excel, ERP and feed in to process Simulation, use to develop KPI Dashboards.

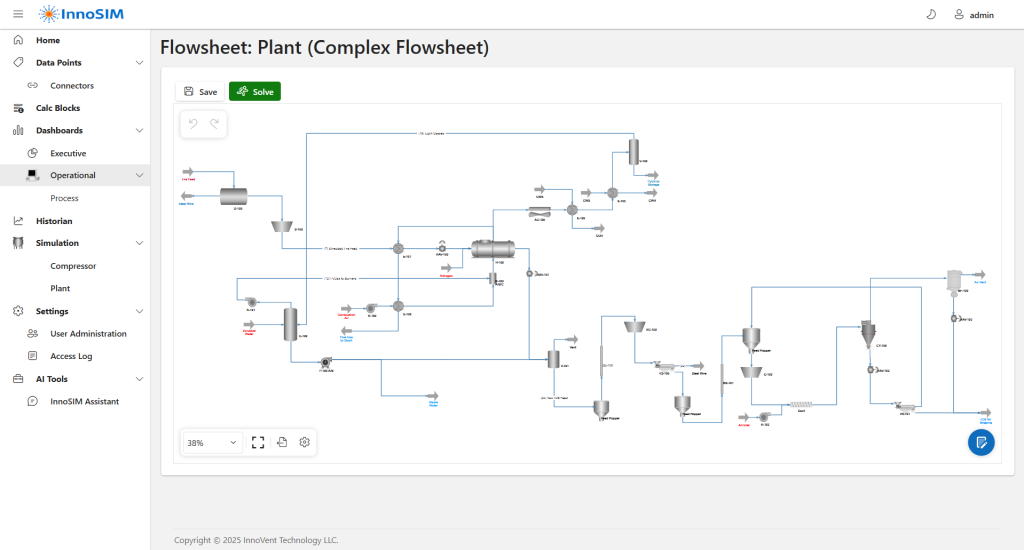

- Process simulation model integration for industrial plants.

- Digital twin asset monitoring with operational insights.

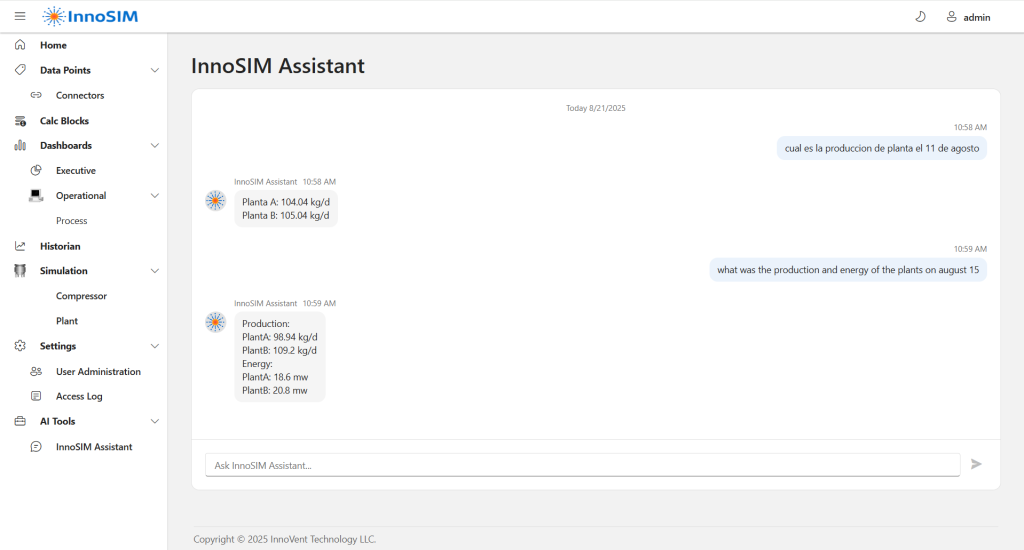

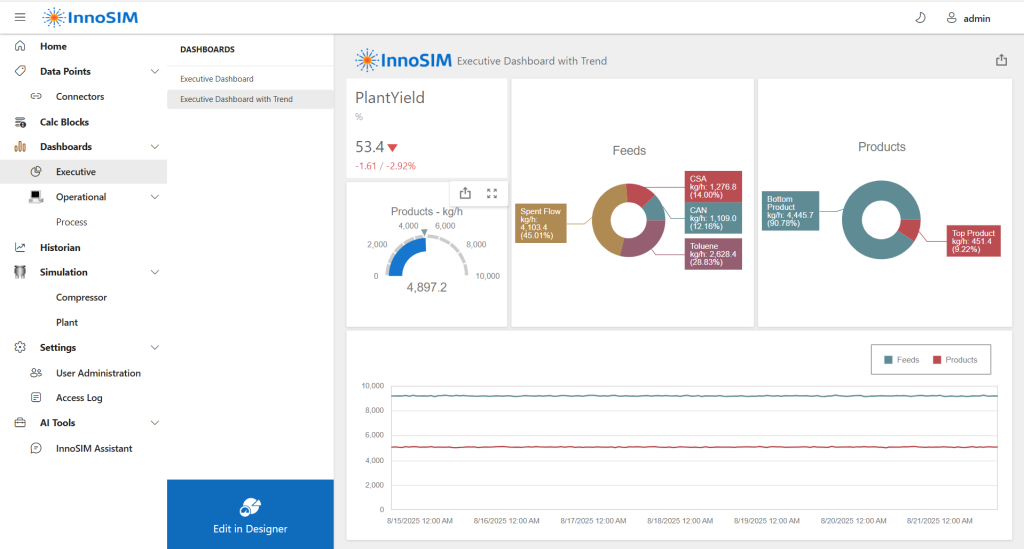

Executive Dashboards and AI enabled decisions

Get production updates using AI, and track executive KPI’s.

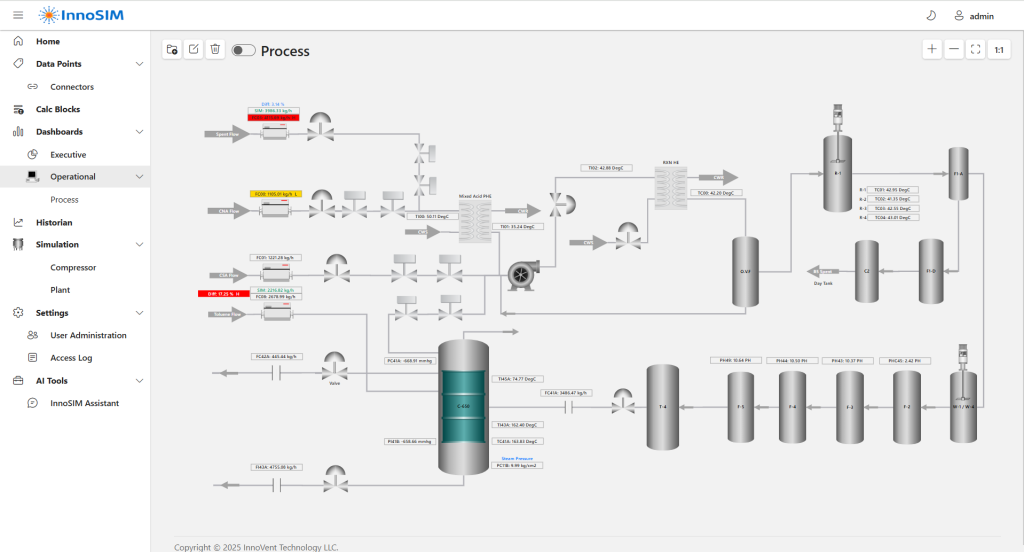

InnoSIM Operational Dashboards

Integrate process simulation models and track operational dashboards, comparing actual values with simulation values to optimize operations.

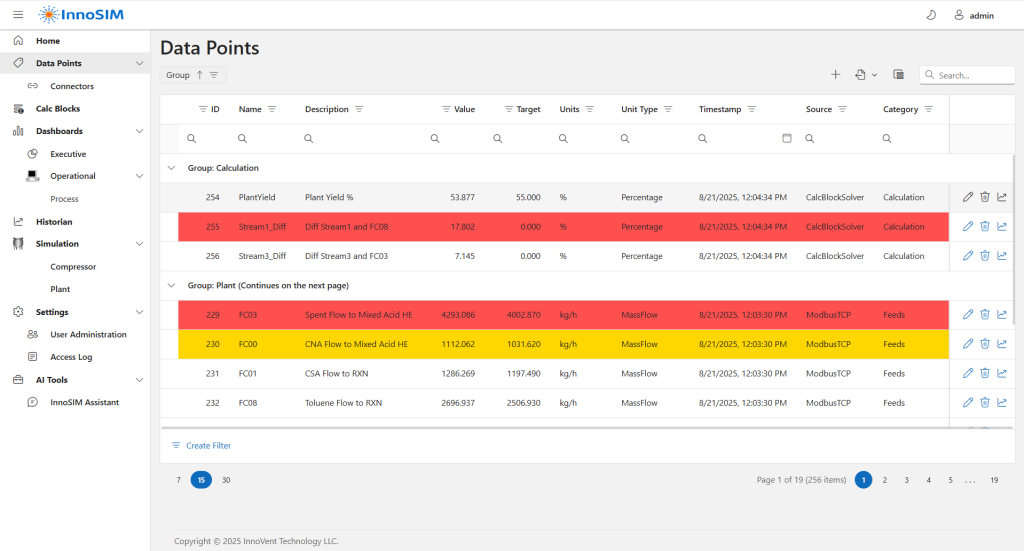

InnoSIM Data Historian and Data Connectors

Real time Data Historian pulling in live data from multiple industrial sources, and connectors to easily link to InnoSIM.

Process Technology Licensing and Engineering

Driving operational excellence using our process industry expertise.

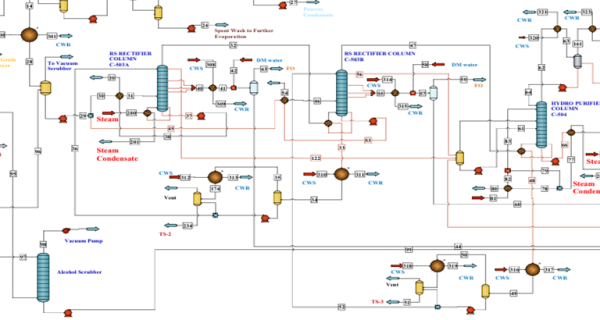

InnoEthanol: Bioethanol Process Technology

- Innovative distillery design, engineering and automation from feed processing to Ethanol (fuel grade) or ENA ( Extra Neutral Alcohol).

- 1G bioethanol plants utilize sugarcane juice and molasses as raw material, while 2G plants utilize surplus biomass and agricultural waste to produce bioethanol. 3G Ethanol is latest which uses off gases/CO2.

- Optimized & flexible design, lower energy consumption, lower water consumption.

- References:

Indian Oil 150k liters per day 2024.

Capricorn distillery, 60k liters per day, 2025.

Basic and Detailed Design and Engineering

- Conceptual studies, simulation, basic engineering design packages, heat and material balances.

- Design services for preparation of PFD & PID, Design of static equipment, Piping Design, Structural design, and fabrication ready drawings.

- High fidelity process simulation models, reactor modeling and optimization using leading simulation and design software.

- Engineering studies to diagnose and rectify product quality issues, scale-up, enhance capacity, improve energy efficiency and reduce off-spec products.

Clients

Partners

Chemstations’ integrated suite of intuitive process simulation software fuels productivity for chemical engineering projects.

We created CHEMCAD to empower the role of chemical engineers across industry. To enhance their design, analysis, and testing capabilities so they can drive productivity throughout their organizations. Our outstanding technical support engineers make your CHEMCAD experience all the more seamless.

At XL Byte, innovation is a way of life. We think, connect and hatch new ideas to build innovative platforms that solve real-world problems. Being visionaries, what we see is our soul in things aiming to develop products that benefit millions.

XL Byte is a team of software addicts, conveniently headquartered in Bangalore (the garden city of India), Karnataka. We are smart and committed and our passion and creativity is unmatched.

ChemSepT is a fabrication partner. ChemSepT™ is a team of qualified professionals having hands on experience in relevant field of engineering & technology.

Our Team

Vibhu Sharma

CEO

Entrepreneur with a previous successful business exit. Chemical engineer with 27 years’ experience in the renewable, oil & gas, and chemical industries. Prior to InnoVent, Vibhu was VP of Advanced Applications at Wood PLC, a $5 billion engineering and automation company. Earlier in his career, Vibhu was CEO of Ingenious Inc, a technology and energy consulting firm, that was acquired by Wood in 2016.

Gautam Pradhan

Technical Director

Chemical Engineer with about 27 years of process engineering experience in Oil & Gas, Refinery, Petrochemicals, Ethanol and Terminals, utility and off-site units. Gautam has held senior positions in many reputed companies like Wood Plc, Aspen Tech, Distichemi, Ingenious Inc., Triangle Simulation and Grasim Industries Limited.

Jose Rodriguez

CTO

30 years of rich experience in developing innovative technology platforms in the space of industrial digital systems, automation, simulation and asset monitoring. Previously Global Technical Authority at Wood PLC, a $5 billion engineering and automation company. Prior to that, served as CTO of Ingenious Inc, a technology and energy consulting firm, that was acquired by Wood in 2016.

Sergio Treviño

Technical Director

Chemical Engineer with 25 years of experience in polymer and chemical processes, lab and pilot plant systems. Sergio specializes in seamless scale-up and cutting-edge technology integration. He consistently leverages this expertise to drive innovation and elevate project success to unprecedented heights.

Pedro Carrasco

Senior Engineer, Mexico

Mechanical Engineer with an MBA focused on finance, having 22 years of experience. Involved in EPC global projects, 2D drawings for equipment layout, ASME Pressure Vessel material calculations, project management, change control, scheduling, cost management, and resource supervision. Skilled in budgeting, mechanical engineering, and design of plots and drawings.

Arvind Khete

General Manager-Instrumentation & Automation

Design, Selection, Installation & Commissioning of Field Instruments for various plants like Petrochemicals, Pharmaceuticals, Food & Beverages, Distilleries, Boilers etc. Project Management & Supervision. More than 30 years of experience in Turnkey Instrumentation Projects executed in above fields. 23 years’ experience in Instrumentation field. Actual Automation and Instrumentation Manager.

Leslie Madín

Research Chemistry Principal

Industrial chemist with 10 years of experience. She has worked in different areas of chemistry, such as: analytical chemistry, materials chemistry, environmental chemistry, inorganic chemistry and organic chemistry, to develop new materials or chemical products, optimize laboratory practices, optimize processes and improve quality. Currently is the Research Chemistry Principal and Assistant Director.

Natalia

Product Administrator

She has worked in various aspects of project management, including project planning, resource allocation, risk management, budget control, and stakeholder communication. Her expertise ensures that projects are completed on time, within scope, and on budget.

She is dedicated to fostering team collaboration and enhancing project efficiency.

USA

InnoVent Technology LLC

Houston, TX 77005

Mexico

InnoVent Technology LLC

Terranova 329 Int. 203 Leones, Monterrey, N.L. Zip Code 64600

India

Innovent Process Solutions Pvt. Ltd

gautam.pradhan@innovent.ai+91 9168168554